Sub-Zero Heroes: Transforming Industries With Precision Cooling

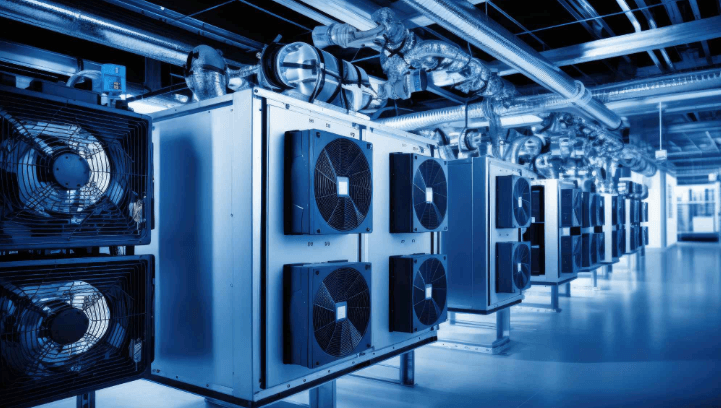

In industrial operations, maintaining precise temperature control is not just a requirement; it’s a necessity that can define the success or failure of processes. The low temp chiller emerges as a pivotal technology in this context, offering unmatched cooling solutions that support a myriad of industries in achieving optimal efficiency and product quality. So, this article explores how these sub-zero heroes revolutionise the field with their advanced cooling capabilities.

The Heart of Precision Cooling

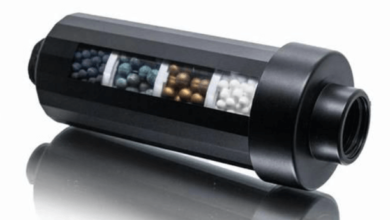

At the core of low-temperature chillers lies cutting-edge technology designed to deliver cooling at temperatures significantly lower than traditional systems. Featuring high-efficiency scroll compressors, electronic expansion valves, and brazed plate heat exchangers, these chillers provide a combination of high efficiency, low noise operation, and unparalleled reliability.

High-Efficiency Scroll Compressors

The scroll compressor is the heart of the chiller and is responsible for its superior efficiency and quiet operation. Unlike traditional compressors, scroll compressors have fewer moving parts, reducing noise levels and minimising wear and tear, extending the equipment’s lifespan.

Electronic Expansion Valves and Brazed Plate Heat Exchangers

Electronic expansion valves and brazed plate heat exchangers fine-tune the refrigeration cycle’s efficiency, ensuring precise temperature control and optimal heat transfer. This precision is critical in applications where even minor temperature fluctuations compromise product quality or process integrity.

Transforming Industries with Advanced Cooling

The low-temperature chiller is not just a piece of equipment; it is a vital component that supports and enhances the operations of various industries, from pharmaceuticals to food and beverage and beyond.

Pharmaceutical and Biotech

In the pharmaceutical and biotech sectors, maintaining specific low temperatures is crucial for the stability of compounds and the effectiveness of medicines. Low-temperature chillers ensure that these sensitive products are manufactured, stored, and transported within the required temperature range, upholding the highest quality and safety standards.

Food and Beverage Industry

The food and beverage industry benefits immensely from the precise cooling capabilities of low-temperature chillers. Whether it’s brewing beer at consistent temperatures, ensuring dairy products are processed safely, or keeping produce fresh, these chillers play a critical role in maintaining the quality and safety of consumables.

The Reliability and Durability Factor

Reliability and durability are non-negotiable when it comes to industrial cooling equipment. The low temp chiller is built to withstand the rigours of continuous operation and features efficient and robust and long-lasting components. This reliability translates into fewer downtimes, reduced maintenance costs, and a better return on investment.

Overcoming Operational Challenges

Industries face numerous cooling-related challenges, from meeting stringent regulatory requirements to reducing operational costs. Low-temperature chillers address these challenges head-on, providing an effective and energy-efficient cooling solution that reduces the overall environmental impact and operational costs.

Read also Breathing New Life into Your Workspace: How Office Refurbishment Specialists Can Help

Looking to the Future: Sustainability and Innovation

As industries evolve, so does the demand for effective and sustainable cooling solutions. The next generation of low-temperature chillers is set to offer even greater efficiencies, lower environmental footprints, and innovative features that anticipate and meet the changing needs of industries worldwide.

Embracing Technological Advancements

The future of low-temperature chillers lies in integrating intelligent technologies, such as IoT connectivity and AI-driven predictive maintenance. These advancements will enable even greater precision in temperature control, enhanced reliability through real-time monitoring, and proactive maintenance, further revolutionising industrial cooling applications.

With their advanced technology and unmatched cooling precision, low temp chillers are indeed the sub-zero heroes of industrial operations. As businesses seek solutions that meet the dual demands of efficiency and environmental responsibility, the role of these chillers is set to become even more central to industrial success. In embracing these advanced cooling solutions, industries are not just optimising their operations but investing in a future where precision and sustainability go hand in hand.